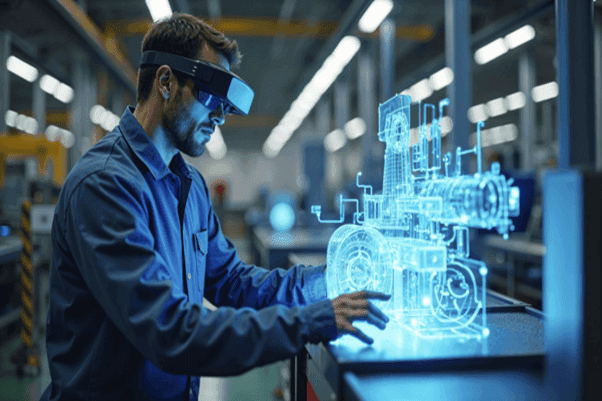

Smarter Shops, Sharper Profits: How Software-Driven Manufacturing is Revolutionizing the Shop Floor Welcome to the Future of Manufacturing

At the intersection of machine precision and digital intelligence, a quiet revolution is unfolding on the shop floor. From massive machining centers to small fabrication setups, manufacturers are embracing smart software solutions to boost efficiency, reduce downtime, and gain real-time visibility into every part of their operations. At the heart of this transformation are tools like ECI Software Solutions’ Manufacturing Execution System (MES), Advanced Planning & Scheduling (APS), and Wintriss’ Tracker hardware — all designed to turn data into a competitive edge.

Digitizing the Factory Floor with ECI MES

Think of ECI MES as the nervous system of a modern manufacturing plant. It connects to more than 140 types of PLC/IO devices, enabling manufacturers to monitor every machine’s performance in real time. With built-in analytics, machinists and operators can now see exactly where inefficiencies lie — and fix them before they become bottlenecks.

Gone are the days of manual tracking errors. Automated data collection reduces human error, while real-time alerts help shops act fast when problems arise. The result? Improved material usage, minimized downtime, and a production schedule that actually stays on track.

Planning Ahead with Flexibility: The Power of APS

ECI’s APS tool complements MES by offering dynamic scheduling. It’s not just about booking jobs on a calendar — it’s about building flexibility into the very fabric of the production process. APS considers real-world constraints like machine availability, tooling readiness, and even personnel schedules.

Even when the unexpected strikes — like a machine breakdown or rush order — APS adapts on the fly. This means shops can plan weeks in advance while staying nimble in the moment. It’s an essential tool for any manufacturer looking to maintain productivity without losing agility.

AI BOM Builder: From PDF to Production

Data entry may seem small, but it's a common source of costly mistakes. Enter ECI’s AI BOM Builder, which automates the creation of Bills of Materials by extracting data from PDFs, CAD files, spreadsheets, and even images. This reduces the tedium of manual entry and ensures fewer errors reach the shop floor.

Integrated with APS and MES, the AI BOM Builder ensures that material availability is factored into the scheduling process from the get-go. That means fewer delays, more predictable workflows, and better visibility across the board.

Wintriss Tracker: Hardware That Thinks Smarter

While software does the heavy lifting in planning and tracking, hardware like Wintriss Controls Group’s Tracker device makes sure the data coming in is clean, automatic, and reliable. Designed for use with ShopFloorConnect software, the WiFi-enabled Tracker collects a wide range of machine data — from run/idle cycles to analog metrics like temperature and pressure — without needing constant input from operators.

One practical example? A metal fabricator used Tracker devices on four air compressors to balance their workload. The result was optimized energy usage and more predictable performance. This hands-free monitoring means that operators can focus on production while the system quietly tracks performance and flags issues in the background.

Seamless Integration, Big Payoff

What makes these technologies so powerful is how well they integrate. From data collection to scheduling, from AI-driven document parsing to real-time shop floor feedback, manufacturers now have a connected ecosystem that empowers them to work smarter, not harder.

And the best part? These tools are accessible. Whether you’re a large-scale operation or a small-to-medium-sized enterprise, there’s now an entry point to modernize without overhauling everything.

The Bottom Line: Efficiency is the New Edge

In a world where supply chain disruptions and labor shortages are the new normal, the manufacturers who will thrive are the ones who can see more, know more, and adapt faster. ECI and Wintriss aren’t just offering tools — they’re offering a smarter way to manufacture.

The digital shop floor isn’t coming. It’s already here. And for those ready to embrace it, the payoff is measured in uptime, productivity, and peace of mind.

Business News

Block Cuts 40% of Workforce as Jack Dorsey Bets Big on AI Efficiency

London Prepares for Robotaxis: Black Taxis Glimpse the Future of Urban Transport

The Best SaaS Content Marketing Agencies: A Comparison Guide for 2026

Where to Actually Find Cybersecurity Solutions (Without Losing Your Mind)

Best Akeyless Alternative in 2026