Sustainable Manufacturing Through Smarter Plastic Molding

If you’ve worked in manufacturing long enough, you know how often sustainability gets treated as a marketing checkbox. You hear the same promises—“greener materials,” “lower carbon,” “eco-friendly operations”—but few actually translate into measurable improvement on the production floor.

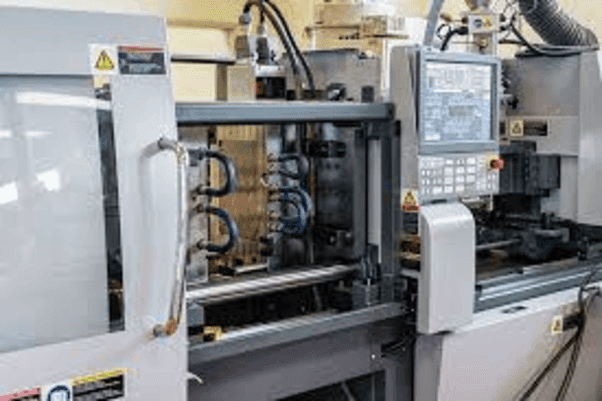

The truth is, sustainability isn’t just a corporate statement. It’s the way you design, mold, and maintain every single part. The factories that get this right aren’t louder about being green—they simply make smarter choices, especially when it comes to plastic molding services.

Why Sustainability Has Become Every Manufacturer’s Challenge

You probably feel the pressure already. Customers ask about carbon footprints. Investors want ESG transparency. Regulators tighten the standards.

The old equation—high output equals high success—no longer holds. Efficiency today is measured in kilowatt-hours saved, not just units shipped.

Plastic molding, for better or worse, sits right at the center of this conversation. You can’t replace every polymer overnight, but you can redesign the way you use it. Smarter tooling, better part geometry, and data-driven production all make measurable impact. Sustainability, when done right, doesn’t slow innovation—it powers it.

How Plastic Molding Became a Sustainability Battleground

You’ve heard the criticism: “Plastic equals pollution.” But that’s only part of the story.

When you compare manufacturing processes, molding remains one of the most resource-efficient methods available. Each shot produces a near-net-shape component with minimal material loss. The waste, ironically, often happens before the press starts running—during design, tool building, and process setup.

That’s where smarter plastic molding services shift the equation. They focus not just on cycle time but on system thinking—how mold precision, cooling efficiency, and machine tuning together reduce energy and scrap. You can’t change the entire global plastic supply chain, but you can make your corner of it cleaner and sharper.

Smarter Design, Less Waste — Where Sustainability Really Begins

If you’ve ever redesigned a part three times because it didn’t mold properly, you know how wasteful poor planning can be. Sustainability starts at the CAD screen.

That’s why design for injection molding is not optional anymore—it’s your first sustainability tool.

When you think about wall thickness, gate locations, draft angles, and uniform flow paths from day one, you prevent defects long before they appear on the production floor. You shorten cooling times, use less resin, and avoid secondary finishing altogether.

Every millimeter you simplify, every second you save, compounds across thousands of cycles. A single geometry tweak can cut raw material use by 10-20%. And that’s not an estimate—it’s something many engineers, maybe including you, have seen firsthand.

Material Choices that Make or Break Your Sustainability Goals

Choosing the right polymer isn’t about jumping on the latest “green” trend—it’s about understanding performance under real conditions.

You know the challenge: one customer demands biocompatibility, another needs heat resistance, and a third wants lower emissions. Balancing those needs takes more than catalog data.

Recycled or bio-based resins are improving fast, but they come with trade-offs in flow stability and tolerance control. You can still use them effectively—if you design your mold to match their behavior. That might mean adjusted gate size, rebalanced cooling, or surface treatments to manage shrinkage.

In our experience, the companies that succeed with sustainable materials don’t treat selection as a last-minute decision. They build long-term relationships with suppliers, run small-batch validations, and collect real processing data. That’s how you align performance with responsibility.

Energy Efficiency Starts with the Mold

You probably think energy optimization means upgrading to an all-electric machine. That helps, but the biggest energy draw in injection molding still happens in your tooling—during heating and cooling. A mold that manages temperature poorly can waste more power in one day than you’d expect in a week.

The solution starts with design. Modern mold manufacturing now uses additive techniques to build conformal cooling channels that follow the part’s geometry. This improves heat transfer, shortens cycle time, and stabilizes dimensions. Lightweight inserts, high-conductivity alloys, and specialized coatings further reduce friction and wear.

The math adds up fast. Saving two seconds per cycle doesn’t sound like much until you multiply it by half a million parts. That’s hours of machine uptime, lower electricity bills, and less CO₂—all because you built the mold smarter.

Smart Monitoring and Automation: Turning Data into Sustainability

You can’t improve what you don’t measure. And yet, many molding shops still run on intuition. Real-time data has changed everything. Embedded sensors now monitor pressure, temperature, and viscosity inside the cavity itself. The moment your process drifts, the system alerts you. No wasted material, no out-of-spec batches.

Automation also takes sustainability from theory to execution. Robots reduce handling errors, vision systems prevent defective parts from moving downstream, and cloud analytics predict when a mold needs maintenance.

For you, this means fewer restarts, more consistent quality, and transparent ESG reporting—because every parameter is logged and traceable.

Circular Manufacturing: Closing the Loop

You’ve probably faced the regrind question: how much can we reuse before properties drop? The answer depends on your material and part function, but modern systems are getting smarter. Closed-loop setups can now reprocess runners and sprues directly back into the hopper, blending them with virgin resin in controlled ratios.

Beyond material recycling, modular tooling opens new doors. Imagine one mold base supporting several interchangeable inserts for different product variants. Instead of commissioning multiple tools, you maximize usage and minimize steel consumption.

Circularity isn’t a buzzword anymore—it’s an engineering reality. The more you can loop material and tooling back into production, the closer you move toward a true zero-waste operation.

The Human Element: Why Culture Still Matters

Technology can optimize, but people decide.

You can have the best machines and the most advanced sensors, but without a team that values consistency and responsibility, the results won’t stick.

Culture drives sustainability. It’s the engineer who questions a design instead of accepting “good enough.” It’s the technician who catches a cooling line issue before it ruins a batch. It’s leadership that rewards process improvement, not just output volume.

We’ve seen factories with modest equipment outperform multimillion-dollar plants simply because their teams cared more about getting it right. Sustainability isn’t a machine setting—it’s a mindset shared by everyone who touches the process.

Practical Steps You Can Take Right Now

You don’t have to rebuild your factory tomorrow to make progress. Start small.

Here’s a checklist that has worked for many manufacturers we’ve worked with:

- Audit your molds. Identify which tools consume the most energy or have inconsistent cooling.

- Track your scrap. Measure, don’t assume. Know your top three waste sources and attack them first.

- Redesign for efficiency. Apply design for injection molding principles to your next product.

- Experiment with materials. Test one recycled or bio-based resin in a controlled environment.

- Automate what you can. Start with quality checks or temperature monitoring; it pays off fast.

- Train your people. Awareness is the cheapest sustainability upgrade you can make.

Small actions compound. You’ll see it in your numbers—less downtime, lower scrap, more stable runs.

Smarter Molding, Greener Future

Here’s the simple truth: sustainability and profitability aren’t opposites. They’re aligned when you approach them with engineering discipline.

Smarter plastic molding services give you control over what used to be unpredictable. Precision mold manufacturing turns energy waste into production gains. And a team that cares turns good intentions into measurable progress.

Every mold you build, every design you optimize, every material you choose tells a story. Make sure yours is one of precision, responsibility, and pride. Because the future of manufacturing belongs to those who know that efficiency isn’t just about speed—it’s about purpose.

Business News

Eric Prydz Accuses Former Business Manager of Financial Misconduct

Berkshire Signals a New Era With a Bold Alphabet Investment

InterDigital Bets Big on AI Video Future with Deep Render Acquisition

Amazon to Cut 14,000 Corporate Jobs Amid Heavy AI Investments

Sustainable Manufacturing Through Smarter Plastic Molding